Project

Innovative Surfaces for Superalloys Casting processes

Participants:

www.icmate.cnr.it

Institute of Condensed Matter Chemistry and Technologies for Energy, Unit of Genoa

comatresearchgroup.unige.it

University of Genoa, DCCI, COMAT Laboratory (Computational Thermodynamics of Materials)

kit.lukasiewicz.gov.pl

Łukasiewicz – Krakow Institute of Technology (former Foundry Research Institute)

specodlew.pl

Specodlew LTD., Polonia

Duration:

4 years ( 1/10/2017 – 30/9/2021 )

www.era-learn.eu

Research programme funded within the EU-H2020 - ERA-LEARN support action, M-ERA.NET Joint Call 2016, Reference Number: project4165

Description and objectives

INSURFCAST aims at finding new solutions for precision investment casting processes of complex-shaped superalloy blades through the understanding of the solid-liquid phenomena occurring at the alloy-mould interface leading to the design, engineering and application of innovative mould surfaces.

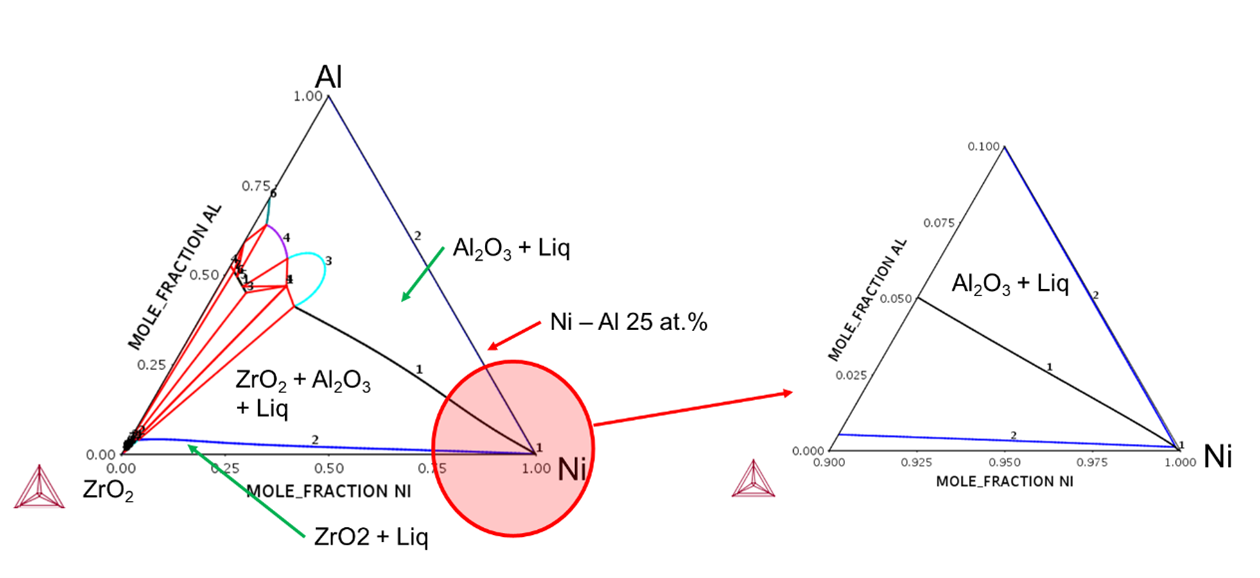

The innovation and technological objective is the reduction of expensive operations of finishing after casting and blades rejections or failure. INSURFCAST involves Italian (CNR-ICMATE and University of Genoa – Chemistry Department) and Polish (Łukasiewicz – Krakow Institute of Technology) research laboratories using several advanced experimental and theoretical methods, in strict synergy and interaction with the metal casting industry (Specodlew – Poland). These innovative results will be obtained through specific wetting tests, microstructural and microchemical characterization of surfaces and interfaces as well as by thermodynamic modelling of the reactivity in selected alloy-ceramic coating systems. Technological trials and post-processing analysis of castings and moulds will lead to optimized casting processes.

The role of the ICMATE-CNR can be resumed in the following points:

- Project coordination.

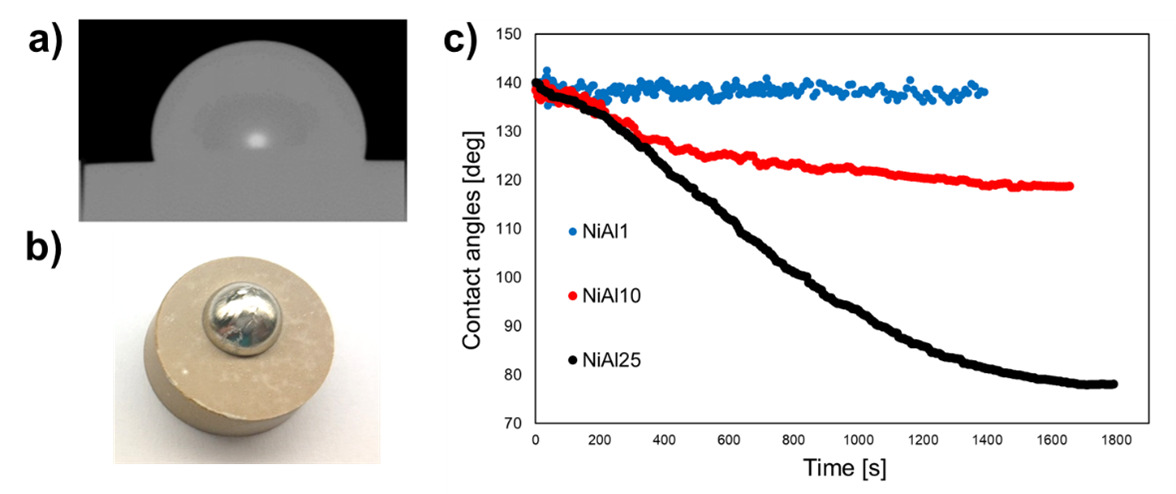

- High-temperature wetting experiments involving liquid superalloys and ceramic materials used for casting.

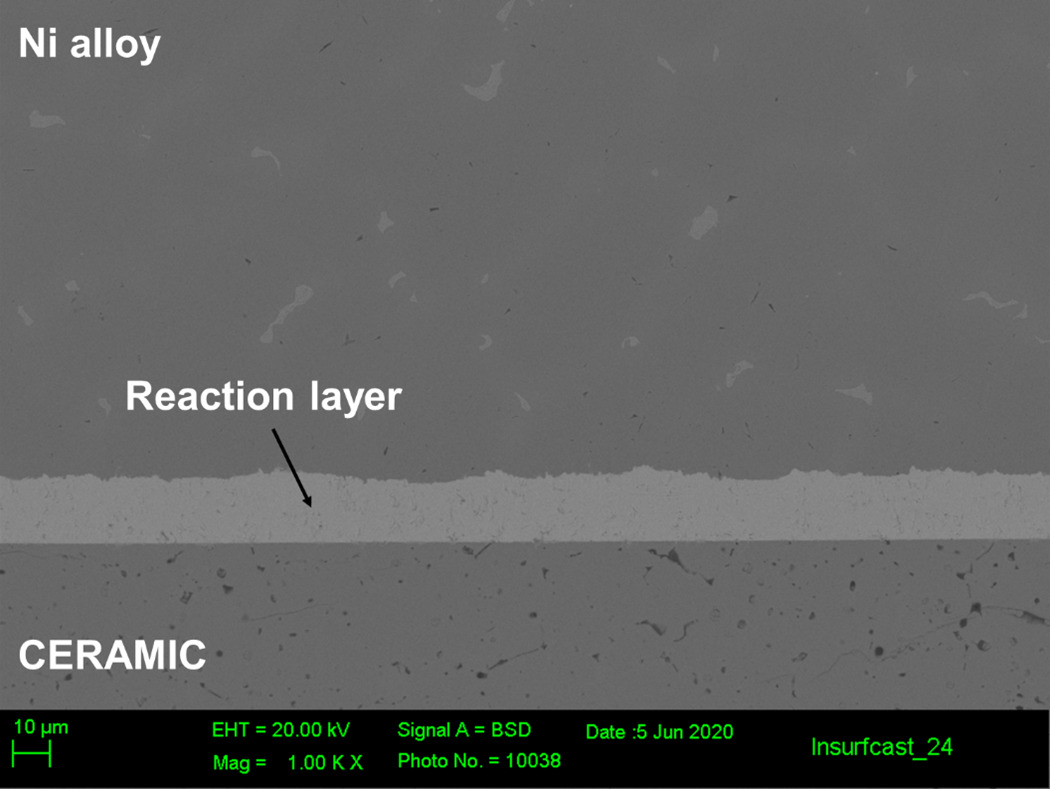

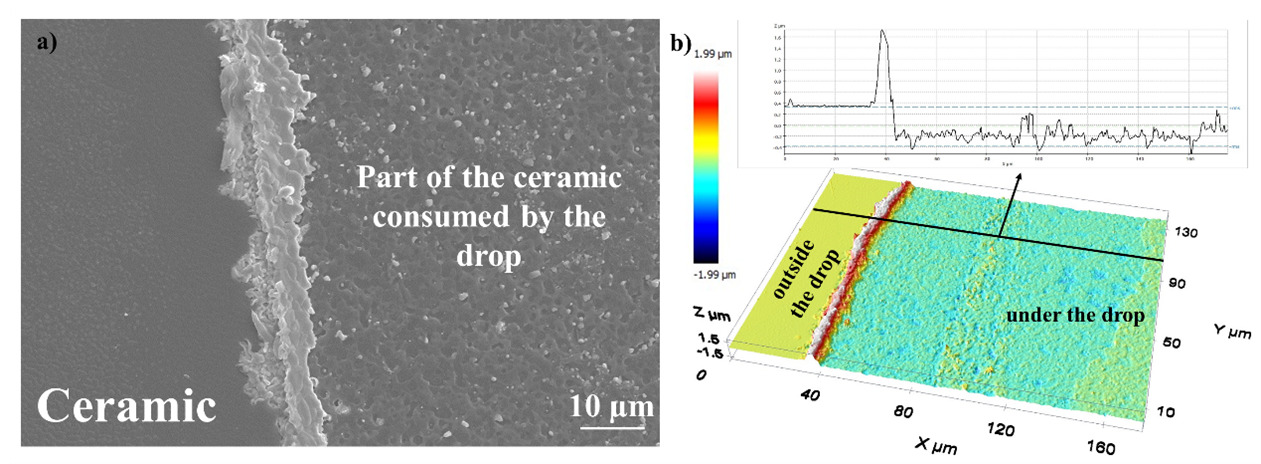

- Study of the interactions between liquid alloys and ceramics for casting processes

- Microstructural characterization of metal-ceramic interfaces.

Contacts

Fabrizio Valenza, CNR-ICMATE